Published on August 3, 2025

Camilla Ferrari

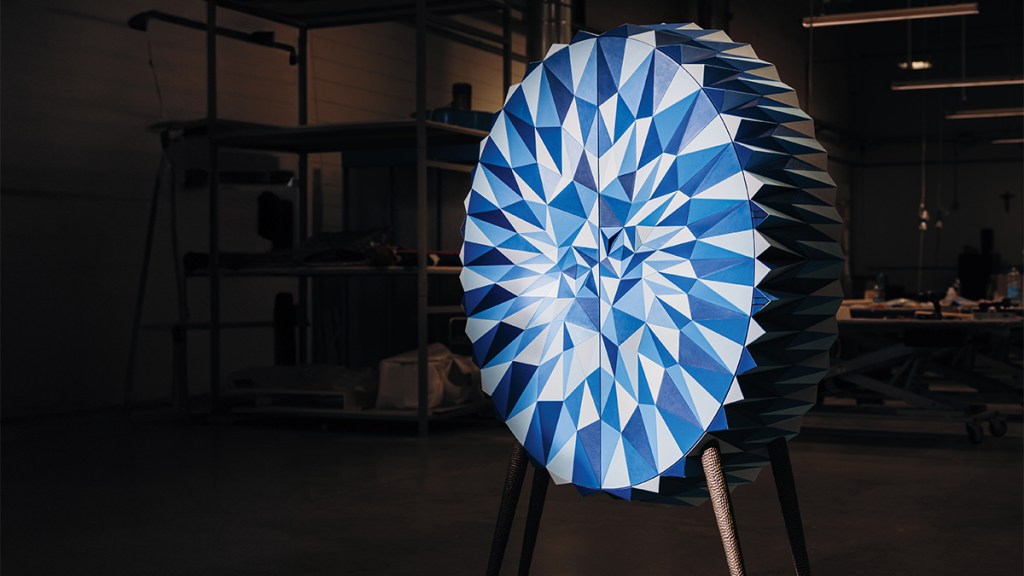

Louis Vuitton's Objects Nomades Collection has long blurred the border between furniture and art – but one of the latest creations exceeds assertive in sculptural areas. The kaleidoscope cabinet designed by Brazil's Estúdio Campana is so complicated that only eight are produced. This version, which was exhibited in Milan during the annual veneer Expo Salone Del Mobile, is an electrically blue monolith, which is dressed in almost 600 individually cut leather triangles, each of which is used exactly to achieve their full effect.

Estúdio Campana was founded in 1984 by Humberto Campana and his late brother Fernando and has worked with Vuitton since 2012. But this is his first cabinet for the French house and one of the most technically ambitious design. Campana introduced the play as a mandala – a circular, structured form that symbolizes the cyclical nature of life.

“It's like Ping-Pong,” he says of the collaboration process. “I give them the poems; they come back with mathematics.”

The transformation into reality required two years of development and the creation of more than 130 customer -specific components, including the hinges with a golden fire and the pulls processed in the inner drawers. Hide his meter machine -cutting, handle hand -seams that the piece takes over four months. (Each example is evaluated on request and available for ordering via the brand's boutiques.)

Open the doors and Vuitton's travel culture in the focus: hidden fans, shelves lined with leather and generous drawers are reminiscent of the ingenuity of the company's earliest tribes. Here is the journey it takes before they are delivered to your home.

-

1. Tan and trim

Photo credits: Camilla Ferrari

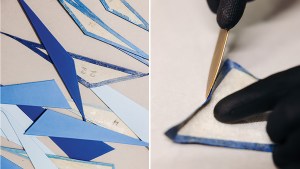

In order to do the colors of the 590 leather triangle of the cabinet, designers brown the skins to reach the right color. Light projectors are used to guide the most efficient placement for each cut. Then each segment is circumcised with a CNC machine. This phase alone lasts over a week.

-

2. Book shape

Photo credits: Camilla Ferrari

A trio of forests is carefully dried to prevent future distortions. The beech doors (see here), ash shelves and Limewood drawers are shaped by the machine, but must be sanded by hand, since the leather or microfiber padding applied to them highlight all defects on the surface below. The full wood structure lasts about two months.

-

3 .. fine -tuning of the pattern

Photo credits: Camilla Ferrari

Each of the triangles is on the closet with removable glue, numbered and meticulously placed on the closet. Craftsmen use bone folders and AWLs to align the pattern by hand and too fine. As soon as the triangles are perfectly positioned, they are glued, polished and inspected – like assembling a puzzle, only with higher operations – which is required over a month of work.

-

4. Hide

Photo credits: Camilla Ferrari

The adjacent hinges that sit flush with the body are used to fasten the doors. Although they cannot see much of them, the hinges and their Pivot pencils have a hidden stop mechanism so that the closet remains open if they want it. To hide the inner screws, the interior is lined with microfiber panels that cover different mechanisms.

-

5. Handicrafts

Photo credits: Camilla Ferrari

In order to create the legs, four unique shapes made of wood are rotated and then carved by hand with a sophisticated pattern. As soon as they are completed, they are used as forms for bronzed bras versions of the legs that are produced with the technology of the free wax. Each leg is hammered by hand and installed with an adjustable foot to keep the cupboard level and then attached to masked points in the frame. A clear protective coating prevents the brass from ageing.

-

6. Signature application

Photo credits: Camilla Ferrari

The LV logo and the Campana signature are applied to one of the leather triangles with a stamp heated to approximately 212 degrees. This requires a perfect timing – a second too long lead of the leather; Too short and the impressions blurred.

-

7. End assembly

Photo credits: Camilla Ferrari

The finished closet weighs more than £ 350. It takes two people to gather and up to five people to assemble it safely on the legs. This includes the installation of the shelves and the properly oriented component.

-

8. Padded packaging

Photo credits: Camilla Ferrari

The curved lower drawer, which was shown here in the end product, was so difficult to construct that Campana says that the project was “almost broken off”. As soon as the closet is complete, the closet is packed in a specially built wooden box with padded interiors to ensure that it arrives in a flawless condition.