London's thrown away coffee cups to take away in Cupsan, a new biomaterials that produced local design practice -blast studio on a scale.

Cupsan is a warm and most defined material that marries the structural qualities of stone and earth. It can also be shaped in forms to produce objects such as trailer lights.

The Blast Studio has been presenting quiet versions of Cupsan for years, since the material originally served as a substrate for the pioneering work of the designers with Myzel.

Myzel can be grown on many carbon -rich waste materials such as straw and sawdust, but the Blast Studio began to use coffee cups with disposable, as it moved from Paris to London in 2019.

“In London we were hit by the sheer number of people who walked around with coffee cups to take away,” Paola Garnootet Paola Garnouset said to Dezen. “We also knew how problematic these cups of recycling are – they are lined with plastic and contaminated with food so that most of them land on landfills.”

However, the designers finally concentrated less on Myzel and more on their paper pulp substrate after he realized that the Mycelium had its limits while her substrate was strong enough for herself.

“Myzel requires sterilization, very controlled growth conditions and it is only slowly in scaling,” said Garnouset. “Not to use Myzel meant reducing the energy requirement, scaling production more easily and creating a functional material for interiors.”

The path of the team for the commercialization of Cupsan was determined when her supplier, the waste management Company First Mile, delivered a full ton of the disposable coffee cup to her door.

At that moment, the designers were affected by the extent of the problem and found that it only represented one of the 30,000 tons of coffee cup waste that the United Kingdom produces every year – and that was very little done with it.

“We understood that if we wanted a real influence, we had to step out of the laboratory and had to confront the realities of the construction and waste industry,” said Garnouset.

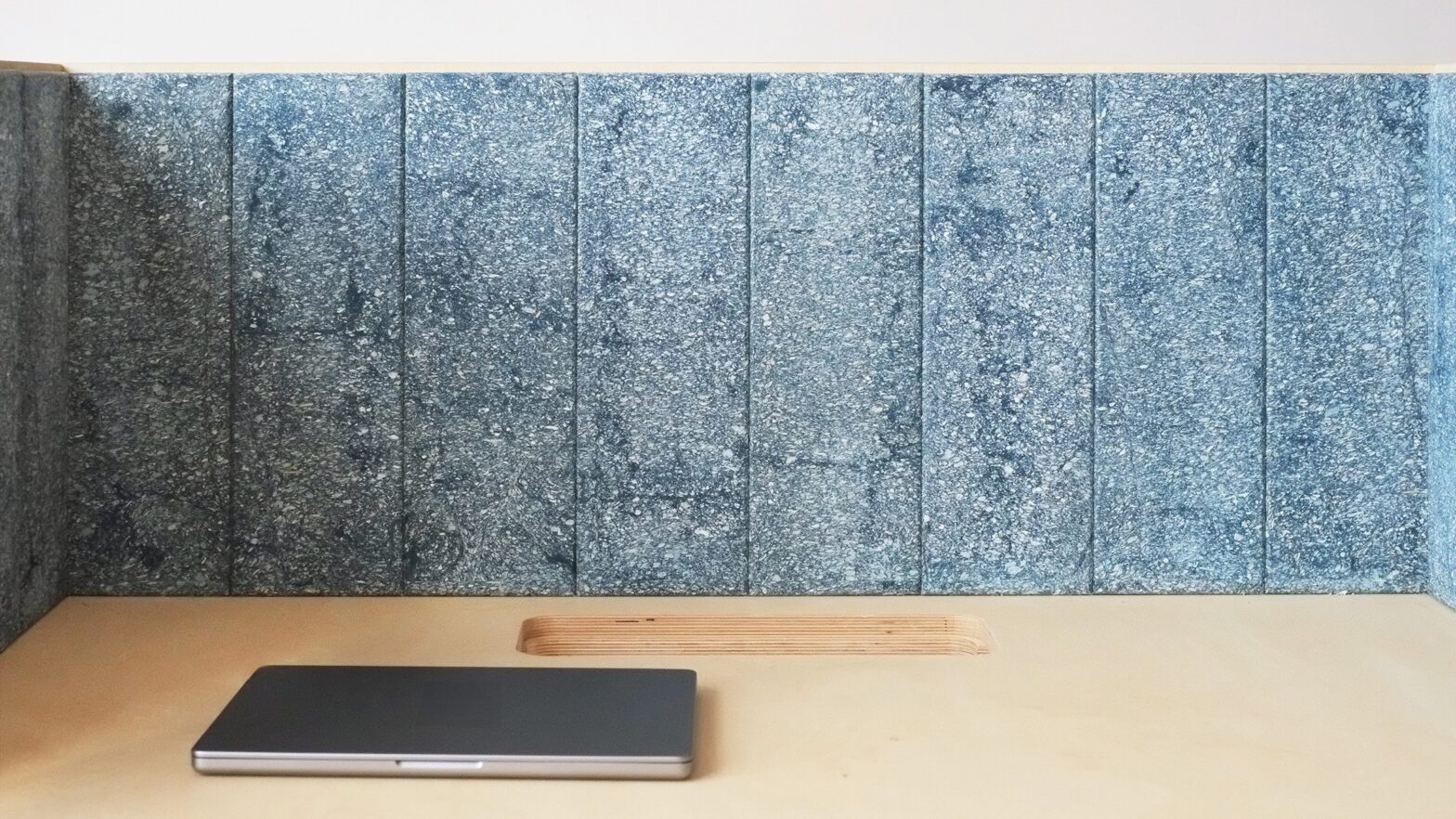

The studio manufactures Cupsan independently and mainly sells it as a board, with each square meter containing around 840 coffee cups.

According to the Blast Studio, the finished material can be cut, drilled, nailed, painted and glued exactly how wood is glued and that it is similarly “forgives” in a similar way, since it can be sanded and repaired in different ways in order to give it new life.

To prepare the material, the Blast Studio hits the cups to create a paper pulp and remove their plastic lining during the process.

The designers add a plastic -free binder to hold the fibers together and have them healed. During this time, the agglomerate texture of the material forms naturally. The binder is a biological formula of strength and vegetable gums.

They sometimes add pigments – mainly natural such as ochres, charcoal and chalk – and also experimented with waste flows such as brick dust to dye the material.

It is also possible to use the existing color in the packaging waste, such as the studio once with the Red Coffee cups from British chains of Gail's and Costa Coffee to a pale pink board.

The studio has also started to test paths to make small design pieces out of the plastic food that is removed during the production process and represents about five percent of each coffee cup.

Black Studio also carries out customer -specific projects with Cupsan, in which the customer's own waste streams are used. For example, the designers worked with TMTO Architecture on the Happy Sky Bakery in Central London, in which lampshades and panels from waste coffee cups from the other location of the business are produced.

Garnouset says that the Blast Studio loved the idea of transforming something ordinary and short -lived from the early days with coffee cups and transforming it into something.

“In a way, it is like putting the coffee cup back into the form of a tree,” said Garnouset. “For us, the cup has become a symbol of the megasty, speed and obstacle.”

“By revising it in Cupsan, we try to slow it down and to transform it into a material that could take decades.”

The earlier work of Blast Studio included the tree column, which was printed 3D with lively myzel and could be harvested for mushrooms before it became a structural building element.