The design and development of printed circuit boards (PCBs) has always been a cornerstone of electronic innovation. From smartphones to self-driving cars, every modern device relies on intricate, well-optimized circuit board layouts. But as devices become smaller, smarter and more complex, engineers are turning to two transformative technologies: computer-aided design (CAD) and artificial intelligence (AI).

In 2025 and beyond, the synergy between CAD and AI is not just a trend but a changing revolution Product design serviceselectronic circuit board design and how we design and deliver the next generation of intelligent products.

What is driving the evolution of PCB design in 2025?

The growing demand for smaller, faster and more energy efficient devices has put enormous pressure on product designers and engineers. Traditional PCB design workflows, while effective, often involve manual iterations, repetitive tasks, and the risk of human error.

The solution? A smarter approach powered by AI-powered CAD tools that automate decision making, improve accuracy and accelerate time to market.

According to a 2024 report by MarketsandMarkets, the global AI market in manufacturing and design is expected to reach $9.8 billion by 2028, with AI-driven design automation accounting for a significant share. This shift signals a clear trend: automation and intelligence are becoming inextricably linked to modern CAD ecosystems.

How does AI improve traditional CAD product design services?

Artificial intelligence seamlessly integrates with CAD platforms, enabling predictive modeling, data-driven decision making and automated design correction. In PCB design, AI takes the guesswork out of routing, simulation and optimization.

How AI is revolutionizing CAD product design services:

Intelligent component placement

AI algorithms analyze electrical, mechanical and thermal parameters to optimally place components. This reduces heat spots, minimizes disruption and improves efficiency.

Automated Design Rule Check (DRC)

Instead of manually checking complex layouts, AI automatically detects spacing issues, layer conflicts, and trace violations, saving hours of development time.

AI-based predictive analysis

Machine learning models can predict how a circuit board will behave under different conditions, allowing engineers to make proactive design improvements.

Data-driven design reuse

AI helps identify design patterns and reusable modules from previous projects, promoting consistency and reducing development costs.

Error reduction and cost savings

Automatically detecting inconsistencies in early design phases significantly reduces the cost of prototyping and rework in production.

Integrating AI does not replace engineers, but rather enables them to work smarter, faster and more creatively.

Why is CAD still the backbone of PCB design?

Despite the rise of AI, CAD remains the foundation of all design activities. From designing electronic circuit boards to mechanical enclosures, CAD provides the visual, geometric and analytical backbone for engineers.

This is why CAD is still indispensable:

Precision and visualization: CAD tools allow designers to visualize circuit board layers, traces and interconnects in 2D and 3D with unmatched accuracy.

Collaboration opportunities: Cloud-based CAD solutions enable global teams to collaborate in real-time, essential for distributed product development.

Integration with manufacturing: CAD data is fed directly into CAM (computer-aided manufacturing) systems, enabling seamless prototyping and production.

The combination of CAD precision and AI intelligence forms a hybrid ecosystem that expands PCB design beyond traditional boundaries.

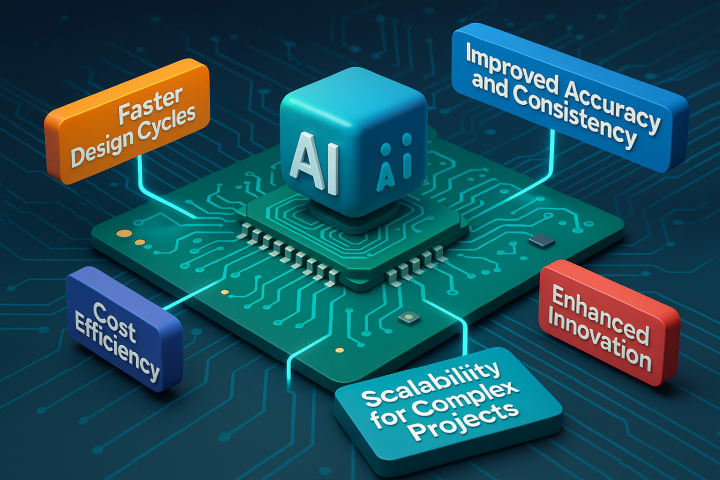

What are the main benefits of AI-assisted PCB design?

Collaboration between CAD and AI opens up several tangible benefits for engineers and businesses alike:

1. Faster design cycles

AI automates repetitive design tasks, significantly reducing project time. This allows companies that offer product design services to deliver prototypes faster and at a lower cost.

2. Improved accuracy and consistency

AI algorithms continuously learn from previous projects, improving the accuracy of design suggestions and ensuring consistency across complex multi-layer PCB designs.

3. Cost effectiveness

By minimizing rework, material waste, and test iterations, AI-driven design tools help companies optimize their budgets without compromising quality.

4. Improved innovation

Freed from tedious manual processes, designers can focus on creative innovation and explore new materials, compact layouts and performance-driven architectures.

5. Scalability for complex projects

AI-powered tools can process large data sets and simulation models, making them ideal for high-density PCB designs in industries such as automotive electronics, IoT and telecommunications.

What challenges still exist in AI-driven CAD design?

While AI brings undeniable benefits, it also brings new challenges that CAD design services in the UK and global markets are still facing:

- Data quality dependency: AI algorithms are only as good as the data they are trained on. Inconsistent or incomplete data sets can lead to design errors.

- Integration complexity: Merging legacy CAD systems with modern AI solutions can be costly and technically demanding.

- Human supervision: Even in automation, experienced engineers are essential to validate results and make contextual design decisions.

- Ethical and safety concerns: AI decision-making transparency and intellectual property protection continue to be a concern for companies handling sensitive electronic data.

How are leading CAD companies in the UK adopting AI?

The UK is becoming a hub for innovation in CAD and AI integration, particularly in circuit board design and product design services.

Leading companies invest in:

- AI-driven simulation tools for predictive analysis and error prevention

- Cloud-based collaboration platforms that connect design and manufacturing teams

- Automated bill of materials creation to streamline procurement

- Generative design algorithms that create hundreds of optimized layout variations in seconds

According to a 2024 survey by Engineering.com, over 58% of UK-based CAD design firms have either adopted AI-powered design systems or are planning to adopt them within the next two years.

This shows strong national momentum towards a digital-intelligent design future, a trend that global companies are watching closely.

What does the future hold for CAD and AI in PCB design?

The future of PCB design lies in convergence, where CAD, AI and cloud computing merge into a single, cohesive environment.

Here's what we can expect in the coming years:

- Real-time AI co-design assistants: Built-in AI agents that suggest design improvements as engineers work.

- Digital twin technology: Simulate physical PCB behavior in virtual environments before manufacturing begins.

- Sustainability-focused designs: AI helps optimize material consumption to meet environmental standards.

- Voice-controlled CAD interfaces: Engineers interact with CAD systems using natural language to make faster adjustments.

- AI-powered PCB repair and maintenance: Predictive diagnostics to detect circuit problems before they cause failures.

The synergy between CAD and AI will continue to democratize electronic design and make advanced PCB technology accessible to startups, innovators and small manufacturers.

Why should companies use this duo now?

In today's competitive technology landscape, time, accuracy and innovation are non-negotiable. Companies using AI-driven CAD product design services can expect:

- Faster time to market

- Reduced operating costs

- Fewer design errors and rework

- Better end-user performance

Ignoring this digital evolution means risking obsolescence in a world that is rapidly moving toward intelligent automation and intelligent design systems.

Diploma:

The alliance of CAD and AI marks the beginning of a new era in PCB design of printed circuit boards and broader product design services. What once required weeks of manual labor can now be accomplished with greater precision and insight in just a few days.

As AI-powered CAD tools continue to evolve, they will not replace human designers but will augment their capabilities and allow them to push the boundaries of creativity and technical excellence.

And for businesses in the UK and worldwide, partnering with a leading CAD design company leveraging this next-generation technology could be the key to developing smarter, faster and more reliable electronic products.