If the automotive industry shifted towards electric vehicles (EVS), the reduction of the weight for improving energy efficiency and driving area has become crucial. Traditional steel components increase robustly, significantly increase the vehicle mass, which leads to higher energy consumption. Composite materials, in particular carbon fiber reinforced plastics (CFRP), offer convincing alternative-a high strength, stiffness and corrosion resistance with remarkable weight savings. Designing composite structures for EVS, however, remains a challenge due to their multiAlal natural and anisotropic properties.

This study deals with this challenge by focusing on the front firewall, a decisive structural component in powerful electric sports cars. In contrast to conventional metals, woven composite materials require a multitial design approach, taking into account the fiber behavior on microscopic levels and at the same time ensuring structural integrity at the macro level. Earlier studies largely focused on mesoscale mechanics and left a gap in holistic design strategies for real automotive applications.

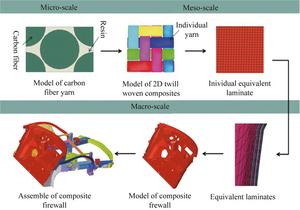

The research team developed a multi-scale modeling and hierarchical optimization strategy for a 2D firewall (2D twilt Woven Composite). By integrating micro-, meso and macroscala analyzes, they predicted the mechanical properties and achieved a maximum error of only 7%significant improvement compared to conventional methods compared to experimental data.

The optimized composite firewall showed weight reduction by 36% compared to conventional constructions and increased the total stiffness by 26%. This breakthrough not only improves vehicle fabric, but also improves crash words and durability. The study also introduced a hierarchical optimization process in which free optimization, size optimization and composite mixture were combined in order to refine the material layout for maximum performance.

The effects of this research went beyond the firewalls: (1) scalability: The multi-scale approach can be adapted to other composite EV components such as doors, roofs and chassis structures. (2) Production efficiency: By optimizing the fiber orientation and layer, production waste can be minimized and the costs can be reduced. . Future work could examine adaptive real -time optimization for dynamic load conditions or hybrid composite materials that integrate recycled fibers for sustainability.

This study is a crucial progress in the composite construction for electric vehicles. By bridging the gap between microscopic fiber behavior and macroscopic structural performance, the proposed multi-scaling hierarchical optimization strategy provides a light, high-strength firewall solution. If the car manufacturers push in the direction of greener, more efficient transport, such innovations will be significantly involved in the design of the next generation of electric vehicles. The state -of -the -art materials science is the key to a sustainable future of the automotive system.

reference

Author: Junfei Yan A BJian Lied ABengang Yi AYi quan ACheng XU AWenyuan Gong AZhaojun you ATengyong Liu AChangchun Xie ADarong Liang AZiao PU AZhenuan Dong A

Title of the original paper

Article link: https://doi.org/10.1016/J.Geit.2025.100251

Journal: Green Energy and Intelligent Transport

https://www.sciencedirect.com/science/article/pii/S2731537250015

DOI: 10.1016/J.Geit.2025.100251

Attorney:

An Automotive Engineering Research Institute, BYD Auto Industry Company Limited, Shenzhen 518000, China

B School of Maschinenbau, Shandong University, Shandong 250100, China

Liability exclusion: Aaas and Eurekalert! are not responsible for the accuracy of news publications published in Eurekalert! through contributions from institutions or the use of information about the Eurekalert system.