In recent years, the HOK inner group has started on a journey to change sustainability in the interior and to focus on healthier building materials. This global initiative, led by a team of 30 interior design connections and consultants, aims to improve the selection of materials in all HOK offices.

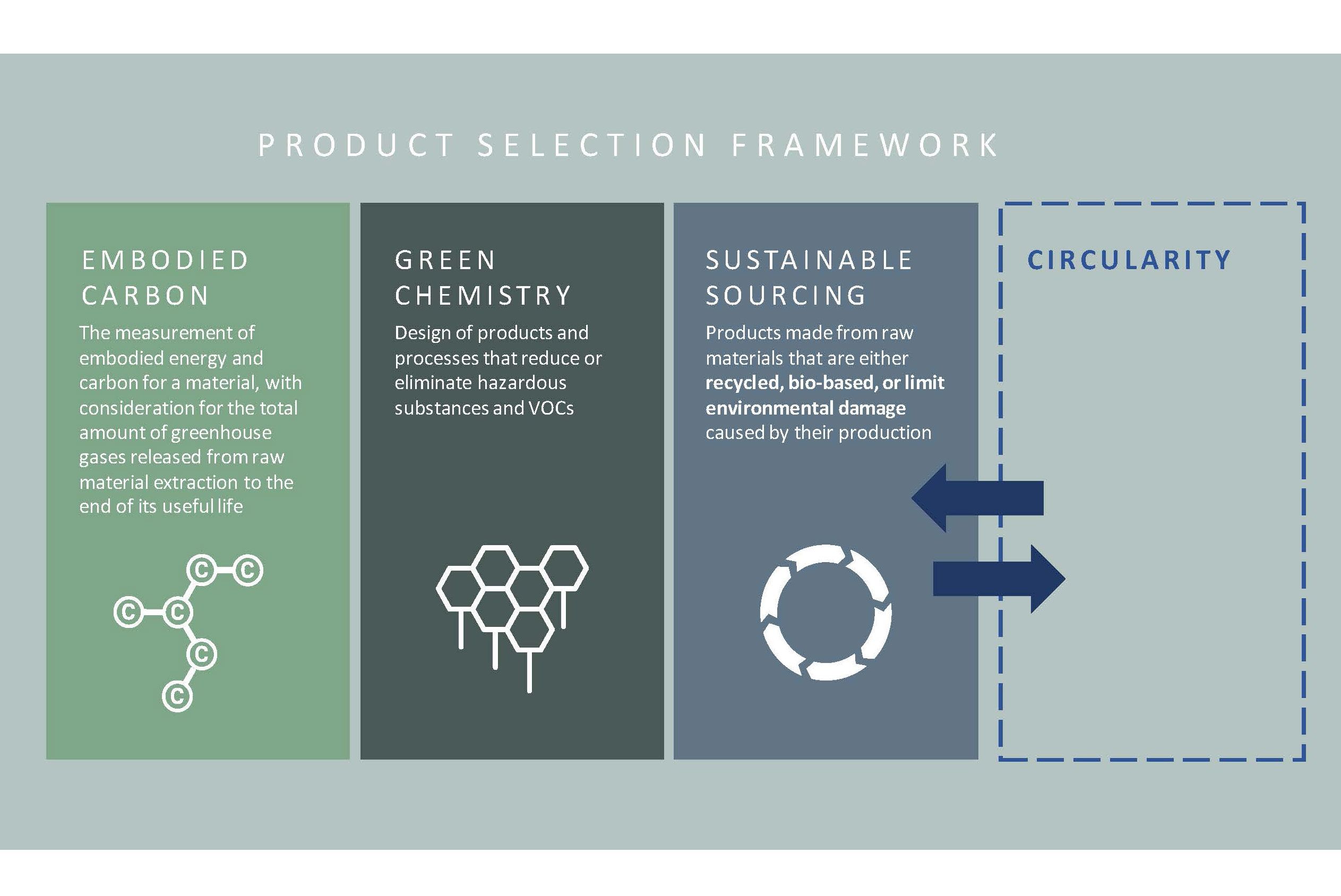

Although they further expand their efforts, the priority was to pursue embodied carbon, green chemistry and sustainable procurement for products for all internal projects, regardless of whether the project for Leed, Well, Bream or Fitwel certification is pursued.

The performance of 2024 for sustainable interior design materials in HOK's projects shows:

- 60% of the materials had environmental product declarations (EPDs) that measure embodied carbon

- 42% had healthy material certifications from third -party providers

- 84% were certified as a low incorporation

- 47% contained recycled content

- 83% used FSC-certified wood

- 12% were classified as reuse or bio -based materials.

By determining strict internal criteria for material health, the introduction of processes for this and the transparent inner group of HOK hopes to influence designers and manufacturers in order to use more sustainable practices.

We spoke to two managers: Christine Vandover, Senior Project interior designer in the New York studio of HOK, and Elizabeth Baxter, Senior Sustainable Design Specialist in Houston. Read on to find out how to work to change designer habits and to advance an industry -wide shift.

What exactly does HOK do to improve sustainability in the interior?

Christine: We have collected data for 4.5 years to pursue sustainability metrics for inner materials. We have set specific goals in relation to embodied carbon, green chemistry and sustainable procurement for our 27 global offices. We also pursue biological content.

We started developing a material tracking tool to embed our design process. We then started it through a series of workshops in the interiors to clarify the designers and specificists from HOK for best practice for healthy materials and the use of the tracker. It doesn't matter whether we design a project for green certification – we want to do this for everyone. Everyone should have access to healthy rooms.

We followed 139 projects in 2024 – an increase of 308% compared to 2021.

Elizabeth: The rooms we design and the products we choose affect human health, climate change and social justice – the three pillars of sustainability. We systematically indicate more environmentally managed products and finish materials such as soil coverings, colors and fabrics.

While we have reached all of our goals, our progress is encouraging. Our goal is that the teams that design every HOK project-5,000 m². Tenant failure at 500,000 m². New buildings – healthy, sustainable materials select and follow. We not only do this because our customers ask about it, but because we are. Sustainability is a large part of Hok's values.

How do material persecution change the habits of HOK designers?

Christine: It teaches our designers to evaluate materials from the beginning via a sustainability lens. Together with aesthetics, they take into account factors such as embodied carbon, chemistry, procurement and circularity. This approach improves the results without adding any additional costs for customers.

How do you approach the manufacturers about this initiative?

Christine: We held over 40 meetings with companies such as Steelcase, Shaw and Herman Miller to share our goals with their sustainability, sales and marketing management. For some of them, we carried out training courses with your company -wide sales teams to understand what we try. We also learn from their sustainability initiatives.

Elizabeth: Since HOK and other construction companies emphasize the importance of healthy materials, we see more manufacturers in their processes and products. And these products are competitive with more sustainable options.

How do you deal with other construction companies to drive sustainability indoors?

Elizabeth: We join our competitors in panel discussions and share information with each other. This knowledge is not something that we consider as proprietary or that we try to keep them. We all want materials to go in a sustainable direction for improving the industry. The most important thing is that we all go forward together.

What are your next steps when expanding the healthy material persecution of HOK?

Christine: Circular design is one of the next borders for sustainable interiors. This includes reuse, renovation and details about dismantling. It enables considerations at the end of life, so that products can step back into the supply chain instead of ending on landfolter. We integrate a checklist for website visit checklist into our process so that designers can identify and evaluate the possibilities for reuse of various elements. Since furniture is generally technologically complex, interiors are ideal destinations for circularity. It is much easier to reuse chairs and floors than for technology manufacturers to find out how they can surround outdated chips. We also work with our specifications, manufacturers and general entrepreneurs to get the right language in the specifications of HOK in order to maximize the recovery in the demolition phase of a project.

We have also stopped an experienced company-wide material and product resource manager, which begins later this year. This person will offer great know-how for research, evaluation and advice from our teams for sustainable, cod-compliant product specifications.

Elizabeth: We only want to specify materials with health certificates from third -party providers. We would also like to align our framework with the common material frame of careful material for better decision -making.

We will continue to be transparent about our goals and results. This will keep us to be accountable and hopefully inspire others in the industry to join us on this trip.