At the age of Industry 4.0, groundbreaking transformations in relation to the construction industry are observed. Digitization has proven to be advantageous for the construction industry, especially through BIM models (building information modeling). This digital transition applies to all phases and aspects of construction projects. Additive production, especially the 3D printing, is a modern miracle. It has gained a lot of attention lately.

In the meantime, BIM and 3DP work seamlessly together. Your integration goes beyond simple data exchange. It examines the procedural, organizational and contextual aspects of these systems. By examining the intersections and correlations between these two systems, we can unlock new possibilities for optimized project workflows, improved cooperation and improved project results.

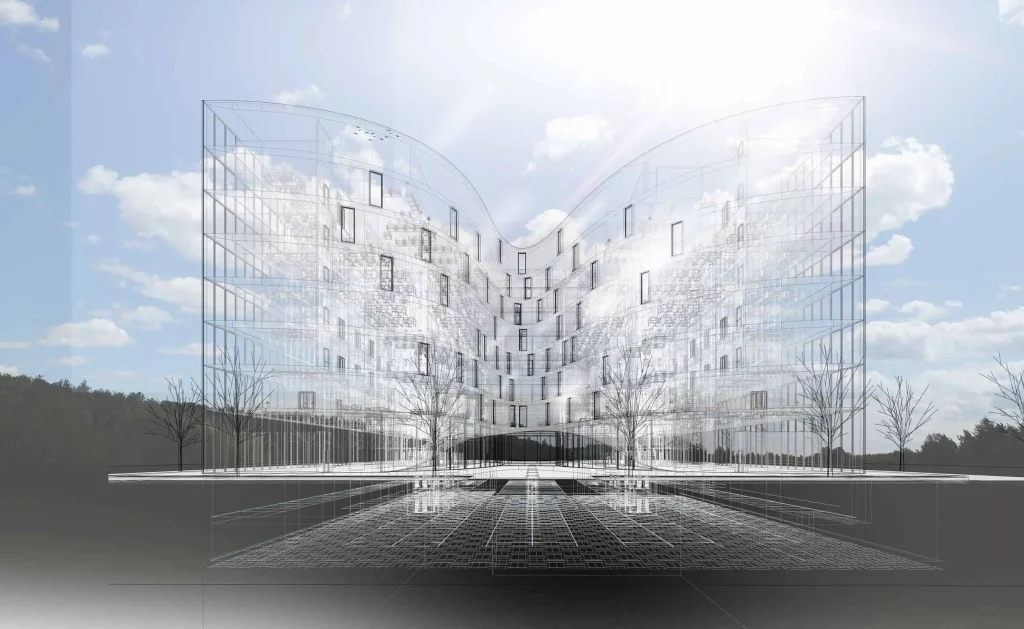

BIM and 3D printing deform the building landscape. They improve the way we design and plan our buildings. This connection promotes digitization through digital DNA by enabling an all-in-one data flow from concept to physical production. The BIM software has changed the architecture by increasing the collaboration.

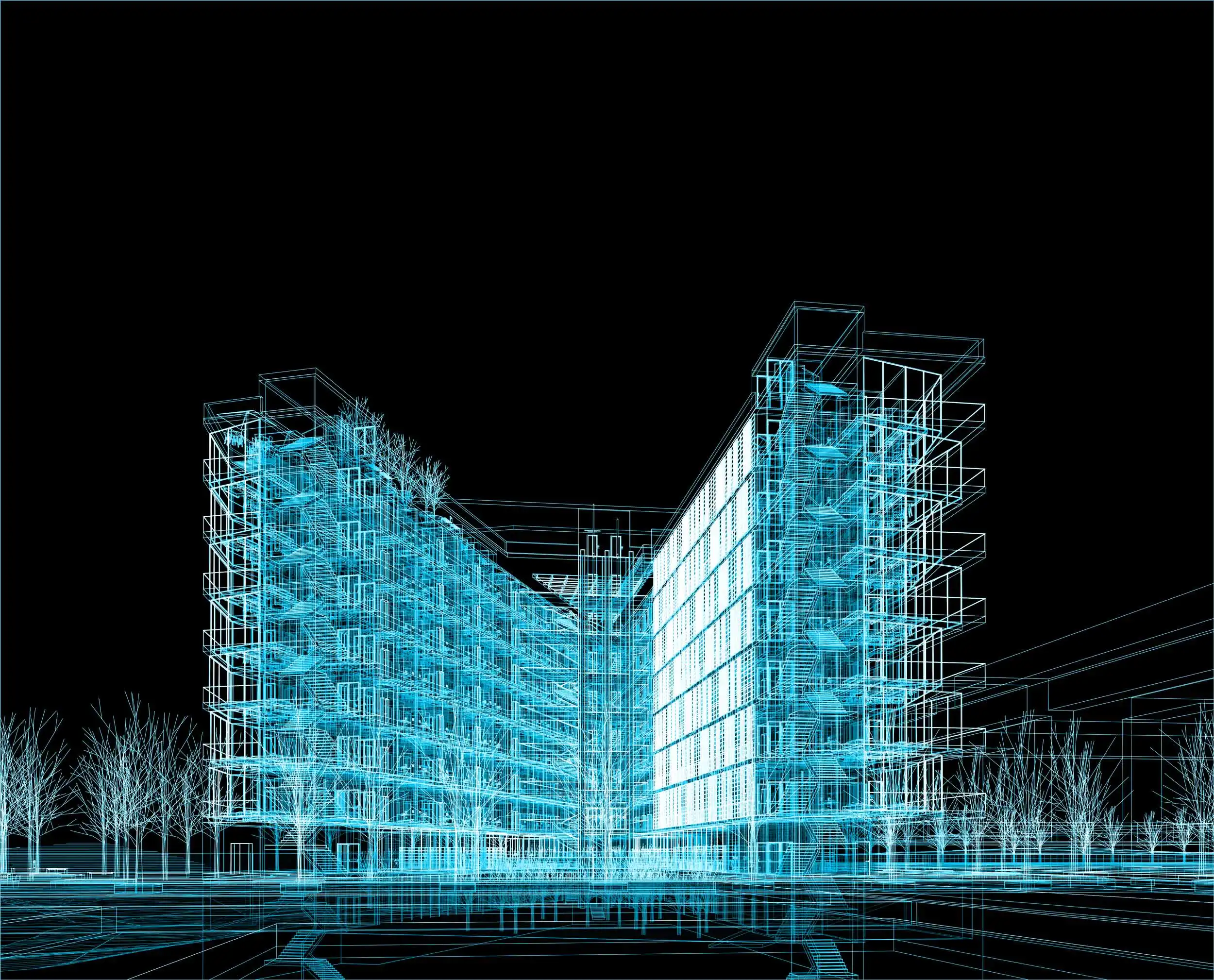

With TOP -BIM tools, architects can visualize ideas, create automated design drawings and easily identify problems. Energy analysis and other characteristics improve the work processes. This helps architects to make it precisely and efficiently. Take this technology to bring your creative visions to life. This technology is used by startups such as Icon and APIS COR to create affordable residential units at significantly lower costs than in the past.

Modern building and BIM

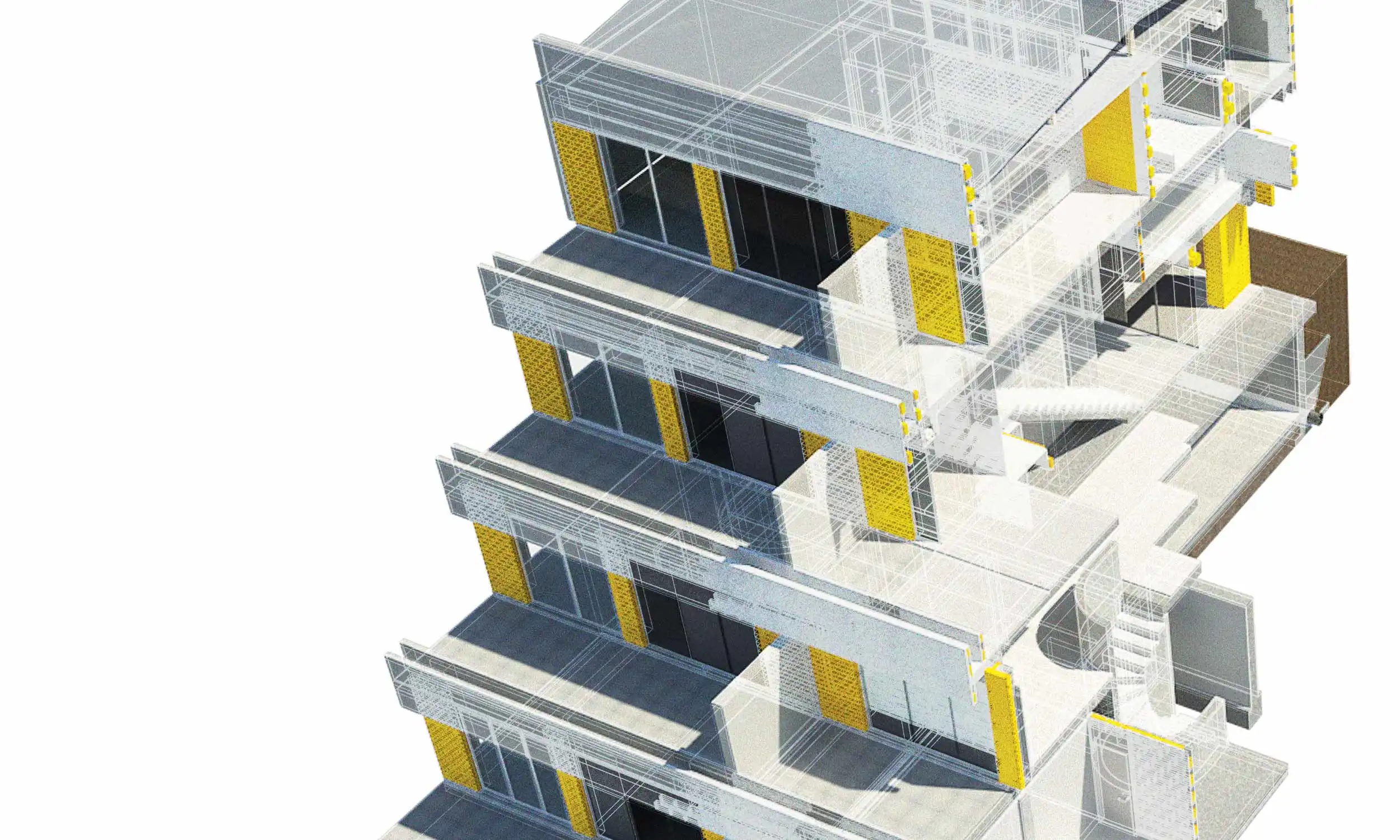

When we talk about the physical and functional properties of a building, BIM should not be forgotten, an innovative method for the development and management of digital representations. BIM works as a powerful tool for architects to design, optimize and visualize projects in 3D. It simply revolutionizes architecture. The global origin and introduction of digital design techniques and automated constructions make it more dominant.

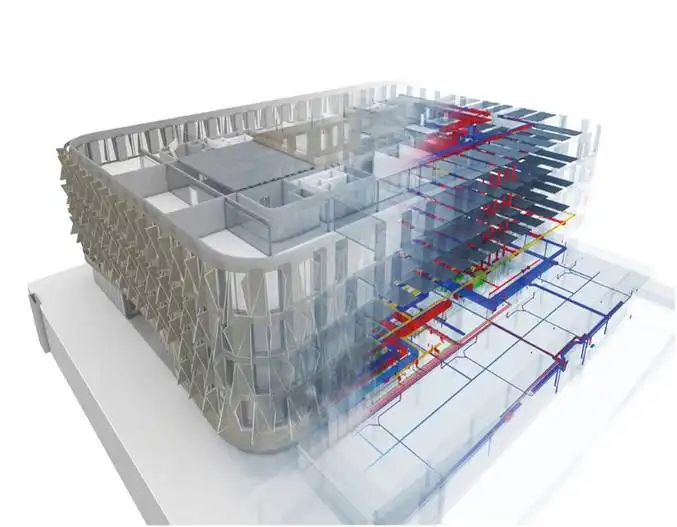

BIM makes more than just digital fingerprints. Project management revolutionizes. It is a multidisciplinary integration and controls real -time data -controlled decisions. Beyond the mere 3D modeling, BIM acts as a treasure troop of information. This repository contains every detail of the life cycle of a building and ensures that nothing is unnoticed. Electrical and sanitary layouts, energy efficiency measuring systems and architectural blueprints are essential components of the digital DNA of the BIM-BIM-BIM-BIM.

BIM production connections

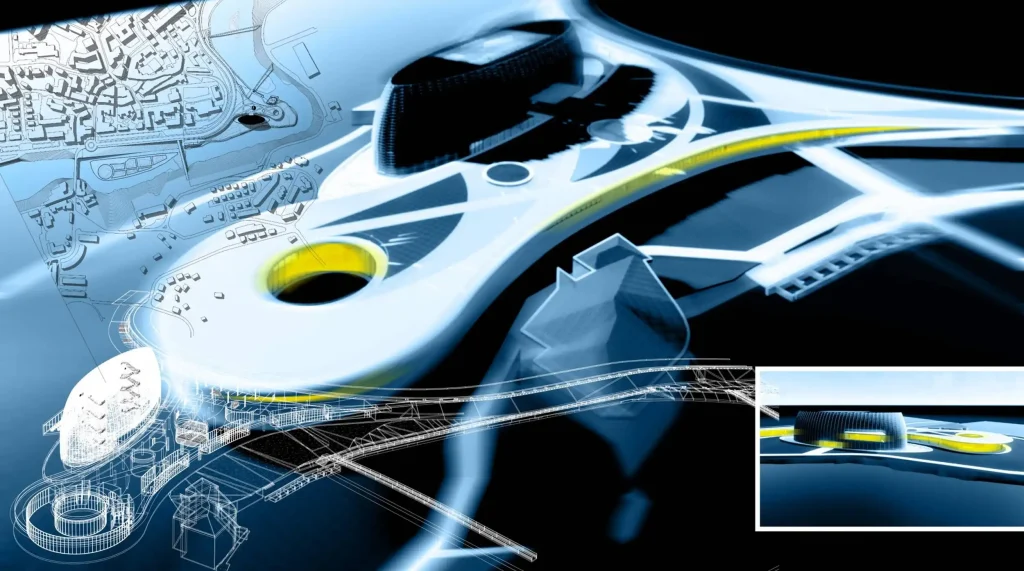

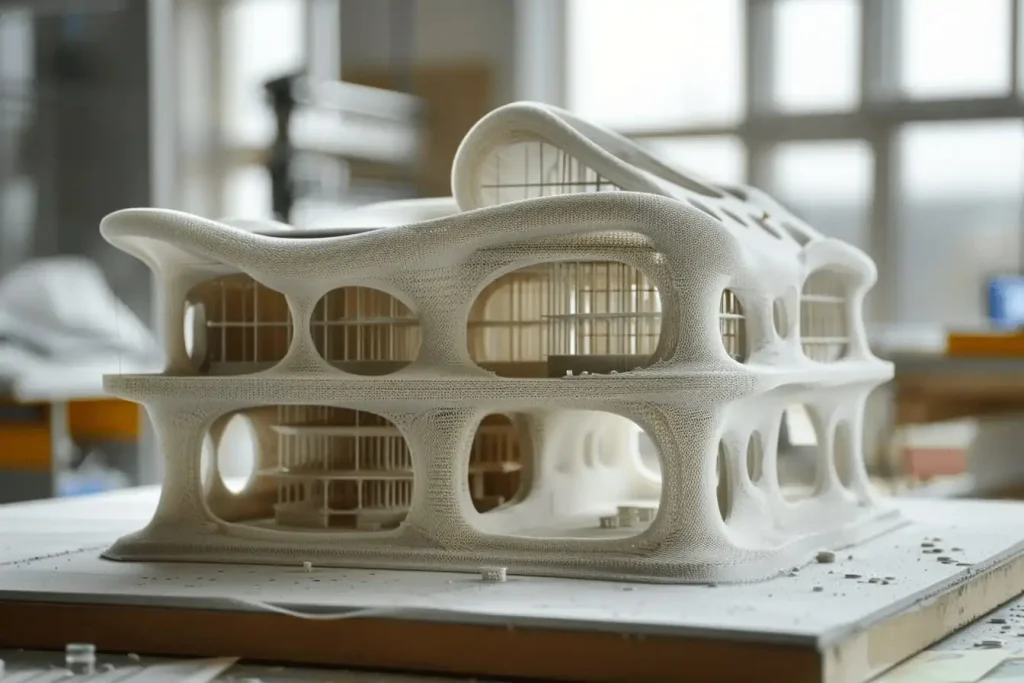

Additive manufacturing, also called 3D printing, records fast growth. This most modern technology is changing the modern production landscape. BIM models drive this important transformation. With 3D printing, we transform digital designs into physical objects and build it up by one layer. This revolutionary technology changes the modern production landscapes radically, similar to the industrial revolution in the 18th century.

BIM models play a crucial role here, act as integrators and the interface with 3D construction pressure and other contemporary methods. The ability to create 3D printing instructions directly from BIM models aroused the developers' curiosity. Factors that influence these models are diverse and range from printing time plans, analyzes of joints, positioning of cavities in components and optimization of pressure routes, each critically influence the final output and even the amount of material used in pressure processes.

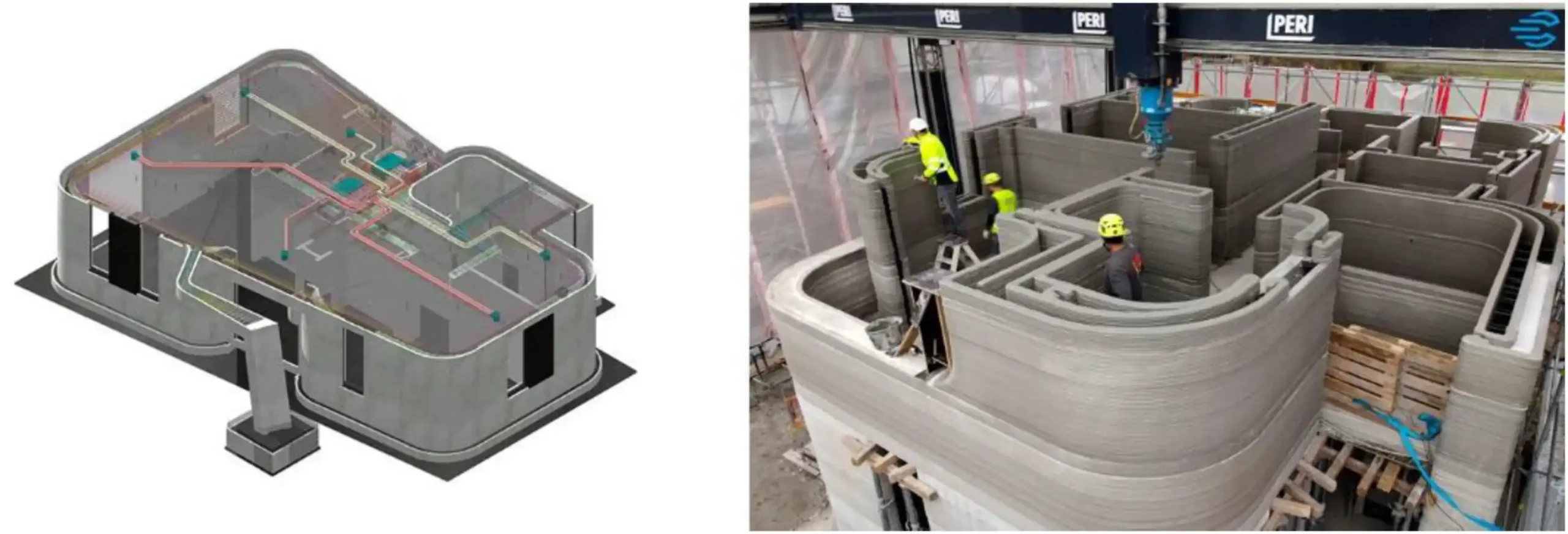

The basic workflow to prepare designs for the prints

Design: BIM software such as Revit, Archicad or Bentley Systems is used to define the geometric shape of the building. All work details of the structure must be included in the BIM model.

Data change: The BIM model is then prepared for the 3D printing. This includes converting the BIM data into a format compatible with 3D printing software, typically a STL or object file. In this phase, necessary adjustments are made to ensure that the model is suitable for printing, e.g. B. scaling and orientation.

Cut: The prepared model is imported into the layer software Ultimaker Cura or others that divides the model into thin horizontal layers in order to create linear contours between certain structure heights. In order to create every level of the model, the Slicing software G-Code, which is the set of instructions, generates.

Material selection: Suitable printable material mixture The selection with specific considerations such as the thermal properties of materials that are used in mix, flexibility and strength.

Press: The prepared model is imported into SNIT software, a kind of digital workshop. Here it cuts the model into thin, horizontal layers and creates linear contours in defined heights. For each level, the software G-Code-a exact series of instructions that lead the printing process generates.

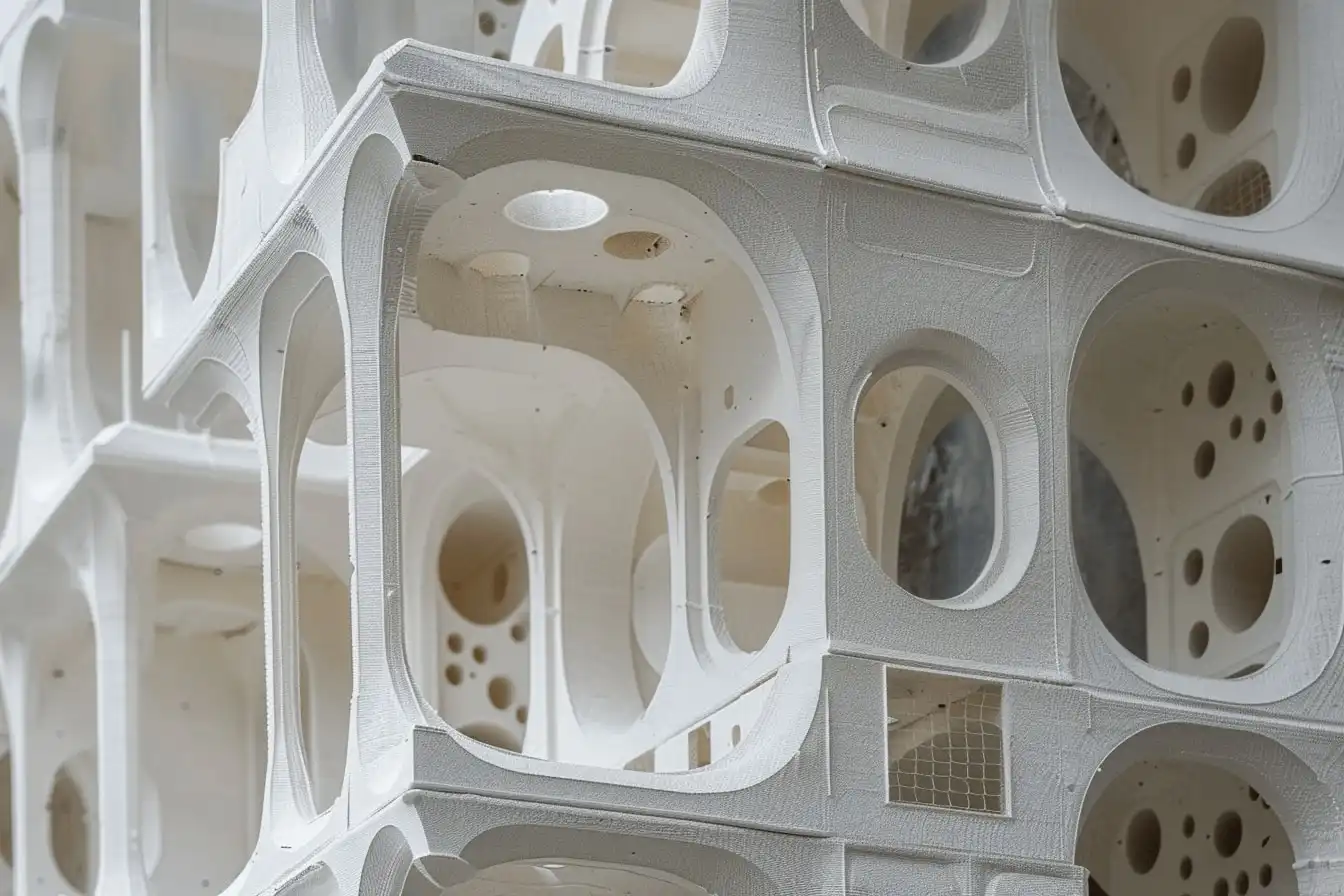

Post -processing: As soon as printing is complete, the components enter the finishing touch phase. They could be cleaned, sanded or treated to refine their appearance. After their transformation, the parts are carefully compiled according to the BIM model. This meticulous orientation guarantees that you insert yourself into the great design without errors.

Quality control and validation: The last phase is quality control. Here every printed component is inspected. To ensure that you meet all the necessary standard and specifications. Customer satisfaction is the benchmark. The printed parts are compared to the BIM model to check the accuracy and integrity.

Advantages of BIM

Efficient alliance

BIM promotes the cooperation between project takers such as architects, contractors, engineers and manufacturers. With a centralized model, these teams can easily replace information and refine designs. This approach helps you to identify and tackle potential challenges at an early stage. By integrating 3D prints, BIM also enables stakeholders to create real prototypes. There is a better view of the end product. It also helps you to understand the design details.

Faster prototyping

You can request BIM support to identify construction errors in prototyping. With the help of BIM and 3D printing, designers can quickly create models and prototypes. This new type of prototype enables you to perfect design design. The result is considerable time and cost savings compared to conventional methods.

Adjustment

One of the greatest advantages of 3D printing is the ability to create unique parts. If designer combine BIM with 3D printing, you can make custom pieces that fit perfectly with the design of the building. This leads to a better look and better performance.

Reduction in waste

The design optimization with BIM software can reduce waste and increase sustainability. With 3D printing, manufacturers can create exact parts that use fewer resources and generate less waste.

Pre -tanning

BIM models serve as blueprints for the construction projects of tomorrow. These digital designs can make room for 3D printed components, so that pre-site prefabrication can easily be done. This innovation leads to a completely new level.

Structural elements

With the use of BIM, the 3D printing can quickly and accurately produce the formwork, shapes and preliminary supports for complex concrete structures.

Retrofitting and renovation work

BIM models can guide the design and manufacture of tailor -made components for retrofitting projects.

Maintenance and repairs

The 3D printing can be used to create spare parts for building systems and equipment.

Setup optimization

BIM data in combination with 3D printing can help optimize space use and improve energy efficiency.

The digital DNA acts as the basis for current state -of -the -art structures and proves that it is no longer a futuristic idea. In short, there are many advantages when bim and 3D printing is united in the construction design, construction and maintenance. By producing more precise drawings, promoting cooperation, reducing waste and improving quality control, BIM of the construction industry can help to optimally use the 3D printing.

Synergist methods for fusion of BIM with modern 3D printing give the construction area massive growth. Improved visualization, faster prototyping and tailor -made production are some of the advantages. The future of the construction is significantly shaped and automated by integrating the BIM and 3D printing, since the technology continues to progress, such as generative design, AI-controlled optimization and robotics.

Learn with Paacademy: Take part in workshops at Paacademy to learn from the best experts in the industry how to use advanced parametric design tools, AI in design workflows and computer design in architecture!